Don’t know about you but having grown up in Delhi, tea to me means a large cup of well- boiled Masala Chai which people drink to jumpstart their sluggish digestive systems every morning. Sure I know where it comes from (all packets feature the mandatory tea- picker in a tea garden picture), but it’s definitely not a topic anyone of us would have googled willingly.

Driving uphill through vast green plantations, 7500ft above sea level, playing peek-a-boo with the damp white mist, my perceptions about tea were about to be changed irrevocably. Here I am talking about the Kolukkumalai Tea Estate in Kerala; the highest tea plantation in the world and the 2005 Southern Tea Competition Winner of the Golden Leaf India Awards.

To get here, you will need to get to Munnar first. An extra hour drive will take you to Chinnakanal and then the true adventure will begin. Hiring a jeep from Chinnakanal lets you experience the two- hour spine- bracing, lip- pursing ride on a vertical climb through tea plantations and mist. Later in your ride, you will witness Tamil Nadu to your left and Kerala to your right. The jeep ride is sure to give you the world famous Kerala Massage.

The tea factory located here follows the orthodox process of tea-making, surprisingly a seven- step process: Withering, Rolling, Sieving, Fermentation, Drying, Fibre Extraction and Grading. What it means visually is a way of life so old- fashioned and simple at the Kolukkumalai Estate that the two storey factory which was built in 1930 by the British still retains its original wooden panels, staircases, flooring, rafters and machinery. It’s like being inside a warm oven and a sharp smell pervades the entire factory. Lean and energetic workers go about their work having learnt to take the invasion from the plains in their stride.

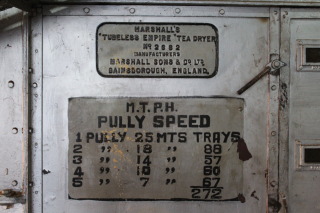

The tour begins by the leaves being withered using hot air and subsequently set to cool down. Then a large roller grinds the withered tea leaves and drops them into a dolly. The tea after fermentation is dried in a large dryer (manufactured by Marshall Sons and Co. Ltd, Gainsborough, England) where the tea leaves go up and down the conveyor belt for a good 25 minutes with varying degrees of heat till they are fully dried. This arrests the fermentation and makes the tea leaves black. Then on the Fibre Extractor where PVC coated rollers and felt- induced static electricity help separate the fibre waste from the tea. This fibre waste is recycled as manure in the plantations.

Finally, it is graded according to the size of the leaf on a sifting machine; the larger the leaf, the more premium the taste and liquor infusion. The dust or the lowest grade “is sold to the railway stations or other such people selling cheap tea.”

You might be wondering what happens in monsoon here in the plantations? Well, life goes on; it’s just wetter than usual.

It seems that the British stumbled upon the magnificent hill ranges of Munnar in the 1800s and after some trial and error figured out they could grow tea here and ship it back to the Empire. So they hired the natives of the hill ranges to clear the woods, make bridle paths, cart the machinery, timber, furniture and even their wives over the rolling hills. In exchange for their labour, they were paid wages in Munnar currency which ceased to have any value in the neighbouring areas, thus ensuring that the workers don’t bolt after the payday.

Over the years, the ownership changed hands from the Empire to private holdings, of which Tata was the largest.

While driving back, I sit back and enjoy the wonders of nature. This wasn’t just a visit but an experience. It is sure to leave you tea- struck for a while.